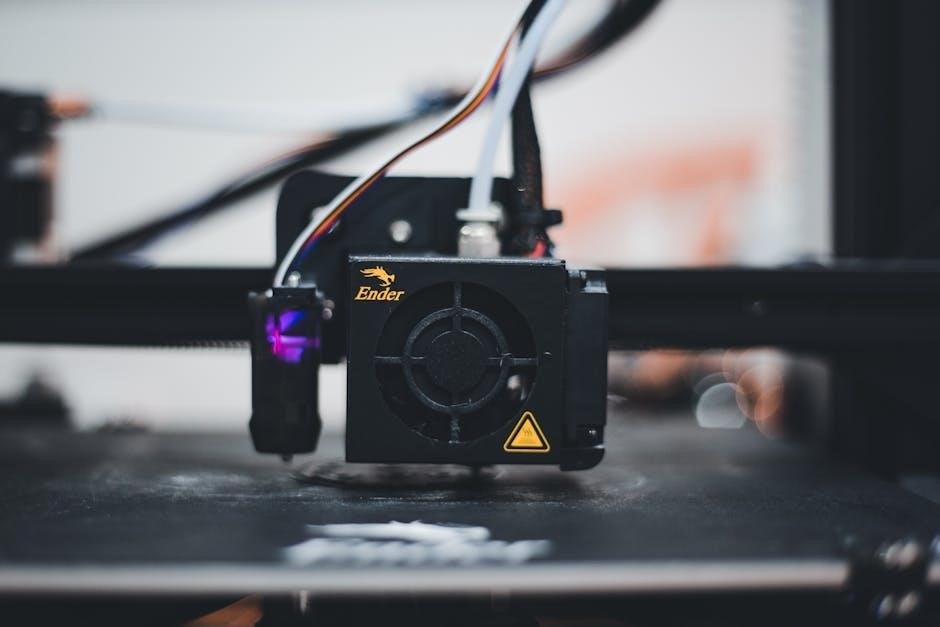

The Ender 3 filament guide is essential for smooth 3D printing‚ ensuring proper filament flow and preventing tangles or clogs. It enhances print quality and reduces downtime.

1.1 Importance of Filament Guides in 3D Printing

Filament guides are crucial for ensuring smooth‚ uninterrupted 3D printing. They prevent tangles‚ clogs‚ and kinks in the filament‚ which can lead to failed prints. A proper guide ensures consistent filament flow‚ reducing wear on the extruder and improving overall print quality. It also minimizes the risk of filament snagging‚ especially with delicate materials like PETG‚ ensuring a more reliable printing experience.

1.2 Overview of the Ender 3 Printer

The Creality Ender 3 is a popular‚ open-source FDM 3D printer known for its affordability and versatility. It features a compact design‚ heated bed‚ and easy assembly‚ making it ideal for hobbyists and professionals alike. Its compatibility with various filaments and extensive community support make it a top choice for achieving high-quality prints with minimal setup and maintenance.

Types of Filaments Compatible with Ender 3

The Ender 3 supports various filaments‚ including PLA‚ ABS‚ PETG‚ and specialty options like metal-filled or wood-based materials‚ offering versatility for diverse printing projects and applications;

2.1 PLA Filament

PLA (Polylactic Acid) is the most commonly used filament for the Ender 3‚ known for its biodegradability and ease of use. It produces minimal warping and requires lower temperatures‚ making it ideal for beginners and detailed prints. PLA is available in various colors and finishes‚ offering excellent layer adhesion and a smooth finish‚ perfect for both functional and decorative projects.

2.2 ABS Filament

ABS (Acrylonitrile Butadiene Styrene) is a durable and impact-resistant filament‚ ideal for functional prints requiring strength. It requires higher temperatures and an enclosed build chamber to prevent warping. ABS is commonly used for mechanical parts and prototypes‚ offering excellent thermal stability. Proper ventilation is recommended due to fumes during printing‚ and adhesion can be improved with Kapton tape or ABS juice.

2.3 PETG Filament

PETG (Polyethylene Terephthalate Glycol) is a versatile filament offering excellent strength‚ flexibility‚ and layer adhesion. It is less prone to warping than ABS and easier to print with than PLA. PETG is ideal for durable parts and functional prints‚ providing a smooth finish. However‚ it can absorb moisture‚ so proper storage is essential for maintaining print quality and consistency.

2.4 Other Specialty Filaments

Beyond PLA‚ ABS‚ and PETG‚ the Ender 3 supports various specialty filaments like wood-filled‚ metal-filled‚ and carbon fiber blends. These offer unique aesthetic and functional properties for specific projects. Additionally‚ glow-in-the-dark and flexible filaments are popular for decorative or mechanical parts. Each requires adjusted settings and proper calibration for optimal results‚ expanding creative possibilities in 3D printing.

How to Install a Filament Guide on Ender 3

Installing a filament guide on the Ender 3 requires basic tools and materials. Follow step-by-step instructions to ensure proper alignment and smooth filament flow. DIY options are also available.

3.1 Tools and Materials Needed

A screwdriver‚ Allen wrench‚ and the filament guide are essential. You may also need PLA filament for printing a custom guide‚ a spool holder‚ PTFE tubing‚ and a spring for proper tension.

3.2 Step-by-Step Installation Process

- Mount the filament guide to the printer frame using screws or clips.

- Attach the spool holder to the side or top of the printer for easy access.

- Thread the filament through the guide and into the extruder.

- Secure the filament with a spring or tensioner for smooth feeding.

- Adjust the guide’s position to ensure proper alignment and tension.

3.3 DIY Filament Guide Options

For a cost-effective solution‚ users can create a custom filament guide using 3D printed parts or simple household items. Print a guide from Thingiverse or craft one using PVC pipe and clips. These options provide flexibility and can be tailored to specific printing needs‚ ensuring smooth filament flow without additional costs.

Choosing the Right Filament for Your Needs

Selecting the right filament for your Ender 3 depends on print requirements‚ material strength‚ flexibility‚ and thermal resistance. PLA‚ PETG‚ and ABS are popular choices‚ each suited for specific applications and printer capabilities.

4.1 Factors to Consider

When selecting filament for your Ender 3‚ consider material strength‚ flexibility‚ thermal resistance‚ and print resolution. PLA is ideal for detailed prints‚ while PETG offers durability and ABS suits high-temperature applications. Color‚ cost‚ and environmental impact are also key factors. Ensure the filament diameter matches your printer’s specifications for optimal performance and compatibility.

4.2 Recommended Brands and Sources

Reputable brands like Polymaker‚ Prusament‚ eSUN‚ and Creality offer high-quality filaments for the Ender 3. These brands provide consistent results and durability. You can find these products on Amazon‚ Creality’s official website‚ or specialty stores like MatterHackers. Always check reviews and product specifications to ensure compatibility and quality‚ ensuring optimal performance for your printing needs.

Maintenance and Care Tips for Filament Guides

Regularly clean filament guides to prevent debris buildup. Inspect for wear or damage and replace as needed to ensure smooth filament flow and optimal printing performance.

5.1 Cleaning the Filament Guide

Regularly clean the filament guide to remove dirt‚ dust‚ or leftover filament residue. Use compressed air or a soft brush to gently sweep away debris. Avoid harsh chemicals that might damage the guide. Focus on the extruder area and PTFE tube to ensure smooth filament flow. Clean after every print job for optimal performance and longevity.

5.2 When to Replace the Guide

Replace the filament guide if it shows signs of wear‚ damage‚ or excessive clogging. If cleaning doesn’t resolve issues like tangled filament or poor flow‚ consider upgrading. Visible cracks‚ misalignment‚ or difficulty feeding filament are clear indicators. Regular inspections can prevent print failures. Replace or upgrade the guide to maintain optimal printing performance and filament feed consistency.

Common Issues and Troubleshooting

Common issues with the Ender 3 filament guide include clogs‚ tangled filament‚ and misalignment. Regular maintenance and proper installation can help resolve these problems effectively.

6.1 Clogged Filament Guide

A clogged filament guide can halt printing by obstructing filament flow. This often occurs due to dust‚ debris‚ or tangled filament. To resolve‚ carefully remove the guide‚ clean it with compressed air or a soft brush‚ and ensure the filament is free from knots. Regular maintenance prevents such issues and ensures smooth printing.

6.2 Tangled or Kinked Filament

Tangled or kinked filament can disrupt printing by causing uneven extrusion or complete stoppage. This issue often arises from improper storage‚ using the wrong guide‚ or spool misalignment. To resolve‚ gently untangle the filament‚ ensure proper spool placement‚ and consider using a filament guide to maintain a smooth‚ straight path during printing.

6.3 Other Common Problems

Besides clogs and tangles‚ users may encounter issues like filament slippage or feeder system wear. Regular maintenance‚ ensuring the guide is clean‚ and using high-quality components can prevent these issues. Proper alignment of the spool and guide also minimizes friction‚ ensuring smooth filament flow for consistent printing results.

Upgrading Your Filament Guide

Upgrading the filament guide enhances performance and durability. Aftermarket options and custom modifications provide improved functionality. Ensure compatibility with your Ender 3 model for optimal results.

7.1 Aftermarket Options

Aftermarket filament guides offer improved durability and functionality. Options include aluminum extruder assemblies‚ bearing-mounted guides‚ and adjustable tensioners. These upgrades enhance filament flow‚ reduce wear‚ and minimize clogs or jams. Ensure compatibility with your Ender 3 model for seamless integration and optimal performance.

7.2 Custom Modifications

Custom modifications for the Ender 3 filament guide include 3D-printed or CNC-machined parts. Users can design guides with specific angles or materials to suit their needs. Some opt for aluminum or carbon fiber for added durability. These modifications often improve filament flow and reduce tangles‚ enhancing overall printing efficiency and customization;

Feeding Techniques for Optimal Printing

Proper filament feeding ensures smooth 3D printing; Align the filament correctly‚ maintain proper tension‚ and guide it smoothly through the extruder to avoid tangles and clogs.

8.1 Using a Filament Guide

Using a filament guide on the Ender 3 ensures smooth material flow‚ preventing tangles and clogs. It directs the filament correctly to the extruder‚ reducing friction and improving print quality. Proper installation and alignment are key to optimal performance‚ ensuring consistent feeding and minimizing the risk of print failures due to filament issues.

8.2 Printing Without a Guide

Printing without a filament guide is possible but requires careful handling to avoid tangles or kinks. Ensure the spool is placed in a way that allows the filament to feed freely without obstruction. Proper alignment and a clean path are crucial. While feasible‚ using a guide is recommended for optimal reliability and smoother printing experiences.

Tools and Accessories for Filament Management

Essential tools include spool holders‚ filament guides‚ and cutters. Accessories like filament runout sensors and gauges ensure proper diameter measurement‚ enhancing overall printing efficiency and filament handling.

9.1 Essential Tools for Handling Filament

Key tools for handling filament include a spool holder‚ filament guide‚ and cutters. A runout sensor monitors filament flow‚ while a filament dryer prevents moisture absorption. These tools ensure smooth feeding‚ reduce tangles‚ and maintain print quality. Regular use of these accessories optimizes the Ender 3’s performance and minimizes printing interruptions‚ enhancing overall efficiency.

9.2 Recommended Accessories

Recommended accessories include a spool holder with a bearing for smooth filament rotation‚ a runout sensor to detect low filament‚ and a PTFE tubing guide for consistent flow. A scraper tool aids in cleaning‚ and a digital scale measures filament usage. These accessories enhance filament management‚ reduce tangles‚ and prevent moisture absorption‚ ensuring optimal printing performance for the Ender 3.

Safety Precautions When Handling Filament

Avoid touching heated components like the extruder or hotend to prevent burns. Store filament in a dry‚ cool place to prevent moisture absorption. Use gloves to handle filament to avoid oil transfer from skin.

10.1 Handling Heated Components

Always exercise caution when handling heated components like the extruder or hotend. Use tools to avoid direct contact‚ as these parts can reach extremely high temperatures. Ensure the printer is turned off before performing any maintenance. Proper handling prevents burns and ensures safe operation of your Ender 3 filament guide system.

10.2 Safe Storage Practices

Store filaments in airtight containers or sealed plastic bags with silica gel to absorb moisture. Keep them in a cool‚ dry place away from direct sunlight. Ensure each spool is properly sealed when not in use. Use vacuum-sealable bags for long-term storage and consider periodic checks to prevent moisture buildup and maintain filament quality for optimal printing performance.

Best Practices for Filament Storage

Store filaments in airtight containers with silica gel to maintain dryness. Keep them in a cool‚ dark place to prevent degradation and exposure to moisture or light.

11.1 Proper Storage Conditions

Store filaments in a cool‚ dry environment‚ ideally between 15°C and 25°C‚ away from direct sunlight. Use airtight containers or vacuum-sealed bags with silica gel to absorb moisture‚ ensuring optimal filament quality and preventing degradation. Proper storage conditions help maintain filament integrity and reduce the risk of jams or print failures.

11.2 Organization Tips

Organize filaments by type‚ color‚ and diameter for easy access. Use spool holders with built-in tensioners to prevent tangles and kinking. Label each spool clearly with filament type and color for quick identification. Store spools upright in a dry area to maintain quality. Consider a spool rack or carousel for efficient workspace management and reduced dust exposure. A drying station can also be useful for moisture-exposed filaments.

12.1 Summary of Key Points

Proper filament management is crucial for optimal printing. Use high-quality filaments‚ maintain guides regularly‚ and experiment with settings; Ensure correct installation and material compatibility. Address issues promptly to avoid clogs or tangles. Store filaments in a dry environment and follow safety precautions. By adhering to these tips‚ you can achieve consistent and high-quality prints with your Ender 3 printer.

12.2 Final Tips for Successful Printing

Always monitor filament flow and adjust guides for smooth feeding. Ensure guides are securely attached and free from obstructions. Regularly clean and maintain guides to prevent clogs. Experiment with different filaments and settings for optimal results. Keep your workspace organized and follow safety guidelines for a hassle-free printing experience with your Ender 3 printer.

Additional Resources for Further Reading

Explore Thingiverse for filament guide models and Creality’s official website for detailed guides. Join 3D printing forums and watch YouTube tutorials for expert tips and troubleshooting.

13.1 Recommended Websites and Forums

For in-depth knowledge‚ visit Thingiverse for filament guide models‚ Reddit’s r/3DPrinting for community advice‚ and Creality’s official forum for technical support. Stack Exchange offers expert solutions‚ while YouTube channels like 3D Printing Nerd provide hands-on tutorials and troubleshooting tips for Ender 3 users.

13.2 Community and Support Groups

Engage with Ender 3 communities on Facebook groups like Ender 3 Owners and 3D Printing Enthusiasts. Discord servers dedicated to 3D printing offer real-time support. Local meetups and Reddit AMAs provide networking opportunities. These platforms foster collaboration and help troubleshoot filament guide issues effectively.